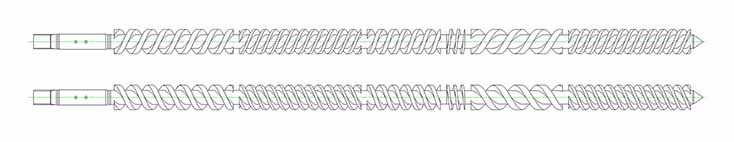

1.1, Put screw A and B into barrel at the same time, install screws and barrel to gearbox, push screws back to gearbox until you can’t push, screw tips all should in barrel, the distance between screw tip and end face of barrel around 3mm.

1.2, Put the probe to the tip of screw A and zeroing dial indicator. Keep screw B motionless, moving screw A forward and record the distance of moving, the distance of moving should be 1.2 to 1.5mm, measuring many times to make sure the data is correct.

1.3, Measure the moving distance of screw B in same way. Make sure moving distances of screw A and B less than 0.1mm by insect and remove shims.

1.4, Push screw A and B back to gearbox until you can’t push anymore. Measure the gap between screw and barrel at the head of screw. The gap should be 0.15t o 0.2mm.

1.5, Installation done.